Home / Industrial Automation

navigation

Contact Person

Factory Add: Hongshan Farm, Economic Development Zone, Xiaoshan District, Hangzhou, Zhejiang, China

subscription

QR code

He magnets are used in a variety of industries, industrialequipments and products. They can be produced by different magnetic materials such as NdFeB, ferrite, SmCo and Alnico material. Furthermore, industrialmagnets can be? magnetic assemblies?which consist of magnet and some other partslike metal, plastic, nylon and etc. The main applications are all kind ofmotors, stators, rotors, generators, engines, couplings, lifters, separators,filters, tools, electric vehicles and so on.

He magnets are used in a variety of industries, industrialequipments and products. They can be produced by different magnetic materials such as NdFeB, ferrite, SmCo and Alnico material. Furthermore, industrialmagnets can be? magnetic assemblies?which consist of magnet and some other partslike metal, plastic, nylon and etc. The main applications are all kind ofmotors, stators, rotors, generators, engines, couplings, lifters, separators,filters, tools, electric vehicles and so on.

Permanent magnet AC servo motor, alsoknown as permanent magnet synchronous servo motor, uses high energyNeodymium-Iron-Boron permanent magnets to provide air gap magnetic field. Thismotor embodies the patented surface magnet assembly technology, whichendows the motors with the highest torque density and compact size.

Servo motor as a rotor is apermanent magnet, the drive control of the U / V / W three-phase power, anelectromagnetic field, the rotor is rotated under the action of this magneticfield, and the motor comes encoder feedback signal to the drive, the driveaccording to the feedback value and the target value, adjusting the angle ofrotation of the rotor. It depends on the precision of the servo motor encoderaccuracy (number of lines).

AC servo brushless motor is alsodivided into synchronous and asynchronous motors, motion control in general arecurrently using synchronous motors, large power range it can do a lot of power.Large inertia, the maximum rotational speed is low, and with the powerincreases rapidly decreased. Thus suitable for low speed applications runningsmoothly.

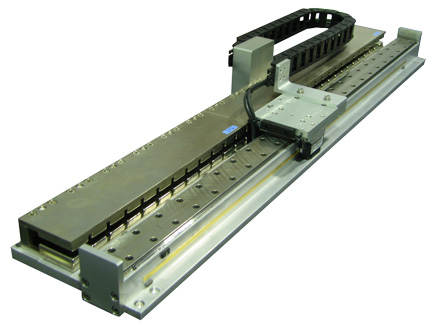

Linear motor

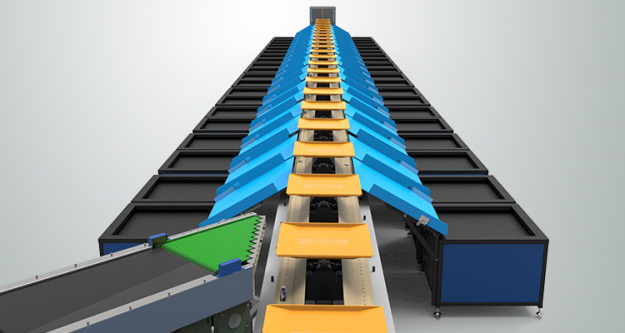

Linear Motors are mostly used inautomatic control system, long time-running driving motors and machines thatrequire large linear power in a short time and within shortdistance. Permanent magnetic linear motor magnet track, whichreplaces traditional secondary coil, can generate smooth and stablemagnetic force although applied voltage fluctuation. It hasmerits of simple structure, non-contacting, non-wearing, low noise,quick speed, high positioning precision and flexible assembly。

Some of its applications are:

--- Logistics parcel sortingsystem

--- Automatic monitoring and feedingsystem

--- Battery sorting system